Year after year, the NTC 5921-1 standard becomes more rigorous for buildings and the vertical transportation industry. The NTC 5926-1 was approved on September 24, 2012 by the board of directors, this standard establishes in a methodical way (schedule, inspection, validation, among others) how an elevator is certified? by the inspection body. In order to check the safety conditions of the equipment and its correct operation.

This standard is applicable to all electric and hydraulic lifts, permanently installed, that serve defined levels, and that are provided with a cabin intended for the transport of people and/or objects, which is suspended by means of cables, chains, or supported by one or more pistons and that moves at least partially along vertical guides, or with an inclination above the vertical of less than 15 degrees.

Learn more about this technical standard.

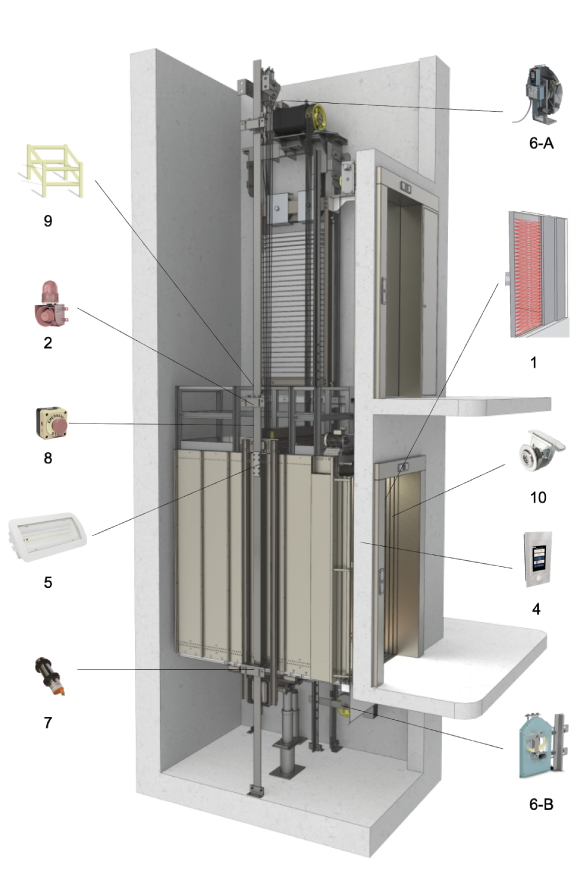

These are some of the safety elements required by the standard for proper certification:

Classification of security elements for users and technicians.

Installation and supply of electronic band memco with infrared ray, this device improves the safety of users, since it allows to interrupt the path of the car doors avoiding blows to users.

Press, heavy-duty platen built into the counterweight of the lift gives better grip and stability for securing weights.

Intercom system that connects the interior of the cabin with the entrance of the building, this component is very important in the event of an emergency by pressing the button on the intercom you can communicate with the entrance of your building.

Battery, light and emergency alarm in the cabin, these elements will be very useful in the event that a user is locked in the elevator; You can use these elements to warn that you have been trapped in the elevator.

Speed regulator, this is a mechanism that controls the maximum speed of your elevator, mechanically and electronically blocking the equipment when it exceeds the established speed.

Weight in limiter, it is an instrument which is made up of a pulley and steel cables, this mechanically blocks the elevator through the fall of a weight which turns on a micro "switch", which proceeds to activate the for falls of the lift. The regulator weight is installed on the car guides 50 cm from the lowest level of the elevator pit, check.

Sensors installed in the lower part of the cabin, which indicate the excess capacity of the elevator.

8

Mushroom safety switches in shaft and top of car, these stop the car completely, in case of an emergency, or when repairs are made to the elevator. In this way the technicians will have security when proceeding with the intervention of the elevator.

9

Enclosure on the car roof, it is a security element which is made up of steel tubes that form a corral, this component provides support to the technicians who are carrying out repairs on the elevator car, preventing the technician from falling in these situations down the elevator shaft.

10

Supply of triangle security keyholes for doors. This element is located in the hall doors of each floor, it is used for elevator maintenance and to access the equipment pit. It is also used in emergency situations or when people are trapped, it serves to safely evacuate users.

Conclusion

During the last years the requirements of this standard have been increasing and evolving, with the purpose of increasing the safety of users who use this vertical transport and technicians who intervene in elevators; In addition to guaranteeing the operation and availability for the use of the equipment,

What safety elements must my lift have to be certified by the NTC 5926-1 standard?

Find out in time about the elements that you must include in your NTC certification

Ascensores Certificación NTC 5926-1 Normatividad