Perhaps you have asked yourself the question: What work is necessary to start with the installation of my elevator? Well, we tell you that in order to guarantee a good process and be efficient, you must make adjustments to civil works and electrical works before the elevator contracting company arrives at the building. At GOLD elevators we divide our execution into three phases: the first refers to the civil works adaptations necessary to install the frames, guides and headboards, the second contemplates the electrical works, to place the cabin, the machine and the control; and the last one focuses on the adjustment and completion of the elevator.

To guarantee safety and efficiency when starting the installation of your elevator, you should check the space where the elevator will be installed. The installation of the elevator consists of 3 phases and for these some requirements are needed according to the progress of the work:

1 phase: installation of door frames (hall) and guides (counterweight and cabin).

2nd phase: installation of the cabin, hoisting of the machine and other electrical and mechanical components of the elevator.

3 Phase: load tests and final adjustments that will give your elevator smoothness and comfort.

First phase

Elevator shaft:

Well plastered and painted white: It is important that when doing this work, the measurements provided in the plans of the well are respected. The plaster applies when the well is in masonry.

Clean well: Well cleaning, according to NTC 2769-1 Chap. 5, in order to prevent civil works debris from coming into contact with the mechanical and electronic parts of the elevator, causing damage to the equipment.

Well with light: Installation of a light system with a minimum intensity of 50 lux according to the NTC 2769-1 Chap. 5, which must go: embedded in the wall, so that it does not obstruct the route or the elevator devices; the lamps (tortoise type) must be located on each floor, additionally on the upper level or machine room and on the lower level (-1.30m); It must have switchable ignition at the beginning and end of the well.

Waterproof well: Waterproofing according to NTC 2769-1 Chap. 5, in order to prevent the mechanical and electronic elements from being melted by contact with water by seepage.

Elevator shaft without pipes or foreign elements: Management of spaces for the exclusive use of the electronic and mechanical mechanisms of the elevator according to the NTC 2769-1 standard.

Doorframes:

Levels in each of the floors: Marking of the height at which the floors will be finished in order to properly install the frames. It is recommended to install 1 stage before laying the floor, as a space of 30cm is needed to anchor the hall frames to the floor.

Axis levels: Marking of the distance at which the doors will be located.

Machine room

The cover, the bottom and the width of the machine room must be at least 2m x 2m x 2m according to the NTC 2769-1 standard.

Hook for machine: Casting of the hook to the well cover, for lifting loads. With a resistance of min. 1,000 Kg, according to NTC 2769-1 standard.

Machine room paneled and painted white. It is important that when doing this work, the measurements provided in the well plans are respected.

Machine room without pipes or foreign elements: Spaces for the exclusive use of the electronic and mechanical mechanisms of the elevator according to the NTC 2769-1 standard.

Safe access: According to the NTC 2769 standard, there must be a suitable place for access to the machine room, for this reason we recommend that the ladder meet the following characteristics: Have a height of less than 4m and a distance of between the wall and the steps greater than 15cm; the width of the ladder greater than 25cm; Provided with a safety mechanism for anchoring people, if the ladder is more than 1.5m, arch protectors must be placed on the back of each step.

Door with lock: According to the NTC 2769 standard, it is necessary to install 2 doors: a door for access to perform maintenance on the machine and a trap door to carry out rescue operations. the doors must have a lock and padlock that guarantees the exclusive access of the elevator personnel to the machine room and to the overrun of the shaft in order to avoid accidents due to ignorance.

Machine room paneled and painted white. It is important that when doing this work, the measurements provided in the well plans are respected.

Machine room with light: Installation of a lamp (tortoise type) with a minimum intensity of 200 lux according to the NTC 2769-1 Chap. 5

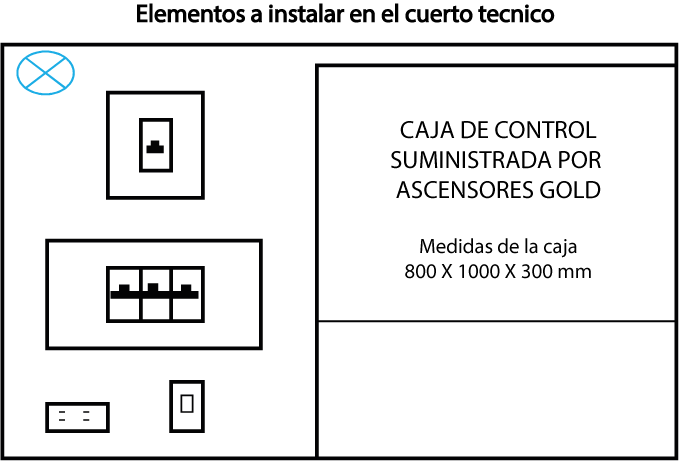

Machine room plate: Casting of the machine room plate according to measurements provided by a representative of Ascensores Gold System Ltda.

Electrical installation:

Three-phase current: Installation of suitable outlets for three-phase and two-phase current (provisional panel) near the pit, 5 meters.

Storage

Deposit to store material: Adaptation of a clean, safe, exclusive place on site and with an area proportional to the size of the elevator, where all the installation material will be stored. If we do not have an exclusive space for Ascensores Gold, we cannot guarantee the finishes of the elevator, since the elements would be exposed to the contingencies of a work and will be the responsibility of the builder.

Deposit to store installers' tools: Adaptation of a place (waterproofed, clean and safe) for storage of installers' tools and utensils, this item applies in the event that the aforementioned deposit is far from the place where the elevator will be installed.

Second stage

Elevator shaft:

Well plastered and painted white. The plaster applies when the well is in masonry.

Clean well: Well cleaning, according to NTC 2769-1 Chap. 5, in order to prevent civil works debris from coming into contact with the mechanical and electronic parts of the elevator, causing damage to the equipment.

Well with light: Installation Light system with a minimum intensity of 50 lux according to the NTC 2769-1 Chap. 5, which must be distributed as follows: - Embedded in the wall so that it does not obstruct the route or the elevator devices; - the lamps (turtle type) must be located at each elevator stop, - additionally one must be located on the upper level (machine) and another lamp on the lower level of -1.30; It must have switchable ignition at the beginning and end of the well.

Waterproof well: Waterproofing according to NTC 2769-1 Chap. 5, in order to prevent mechanical and electronic elements from melting by coming into contact with water.

Pit with ladder for access to the machine: Installation of metal structure according to NTC 2769-1 standard, which must meet the following characteristics: Have a height of less than 4m; the distance between the wall and the steps should be greater than 15cm; the width of the ladder should be more than 25cm; provided with a safety mechanism for anchoring people; If the ladder is more than 1.5m, arch protectors must be placed at the back of each step.

Trap door: Installation of trap doors according to the NTC 2769-1 standard, located on the last stop of the elevator, which must have the following characteristics: Doors open out of the elevator shaft; no perforations or holes.

Doorframes:

Finished floor frames (patterned and painted according to the client's needs): Make an enclosure with the finishes that the client has, but said enclosures must comply with the provisions of the NTC 2769-1 standard, in relation to the required residence, since by not having the proper support the doors can be misaligned.

Corbels to support frames: Casting of supports on which the floor hinges rest.

Machine room:

Anti-slip surfaces: Installation of the engine room floor with anti-slip material according to the NTC 2769-1 standard.

Door with a lock: Installation of a door with a lock and padlock that guarantees the exclusive access of elevator personnel to the machine room in order to avoid accidents due to ignorance. According to NTC 2769-1 standard.

Machine room paneled and painted white. It is important that when doing this work, the measurements provided in the well plans are respected. The plaster applies when the room is in masonry.

Machine room with light: Installation of a lamp with a minimum intensity of 200 lux according to the NTC 2769-1 Chap. 5

Electrical installation:

Plugs for motor, drive and PLC: Two (2) three-phase industrial plugs, one (1) in the machine room at 50 amp and one (1) in the substation of the building, for motor, drive and PLC at 60 amp.

Plugs for engine room and well: Three (3) 20 Amp plugs in the engine room for: cabin light, engine room light and well light (independent of the three-phase plug).

Wiring for the doorphone: Wiring installation for the doorphone in UTP 2X4 category 6A shielded cable, in galvanized tube, it is recommended not to use the elevator shaft for this wiring.

Storage:

Deposit to store material: Adaptation of a clean, safe, exclusive place on site and with an area proportional to the size of the elevator, where all the installation material will be stored. If we do not have an exclusive space for Ascensores Gold, we cannot guarantee the finishes of the elevator, since the elements would be exposed to the contingencies of a work and will be the responsibility of the builder. 5)

Deposit to store installers' tools: Adequacy of a place (waterproofed and clean) for storage of installers' tools and utensils. This item applies in case the warehouse named above is far from the place where the elevator will be installed.

Electrical Requirements:

Make sure you have electricity and that it is adequate for the machinery, as well as: -Installation of:

Lamps with an intensity of 50 lux (tortoise type) on each floor, additionally a lamp on the upper level or machine room of 200 lux and another on the lower level (-1.30m), according to the NTC 2769-1 standard.

Two (2) three-phase industrial breaker: one (1) in the machine room or higher level of 50amp and another of 60amp in the electrical substation.

Three 20 Amp breakers (independent of the three-phase) for shaft lighting, cabin lighting and engine room lighting. Located in the technical room.

Two (2) double intakes upstairs in the engine room and one at the first stop (switchable)

Two switchable switches. Upstairs in the engine room and another at first stop.

Install 2x4 category 6 shielded UTP cable for the interphone (from the control box room to the gatehouse).

Complying with the respective verification of all these aspects mentioned in the course of the installation process of your elevator, you can have the guarantee of an efficient and safe work; so that in the end you have an excellent result at the end of the assembly of the equipment.

In this way, the installation stages will continue, beginning your project, of which you will be able to be aware of all its progress until its completion.

What civil works are necessary before installing my elevator?

Check the status of the civil works of your project to be able to install your equipment

Ascensores Equipo nuevo Proyectos